+Categories

|

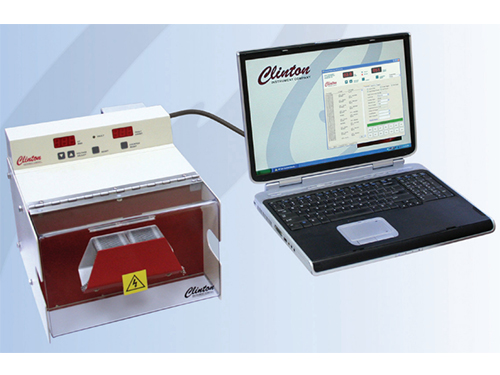

Coordinating old and new technologies on the production line is a challenge for today’s wire and cable manufacturers. While real time device communication with centralized process control is increasingly important to the industry, control systems range from simple, older devices to sophisticated Programmable Logic Controls (PLCs) and computers.

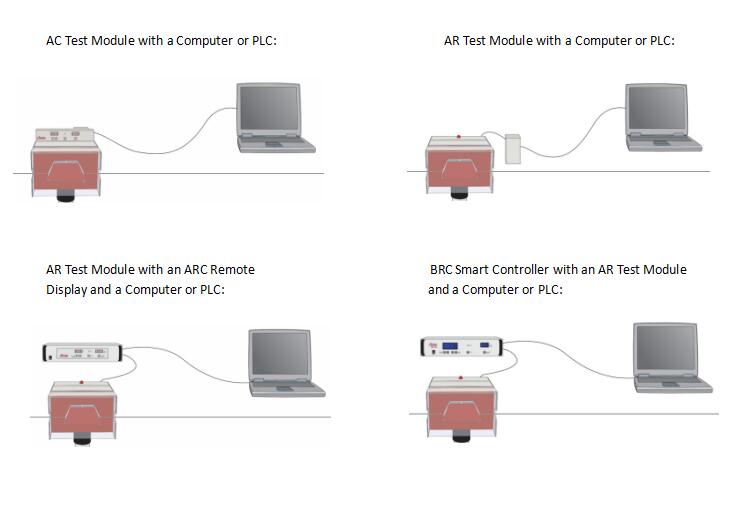

With so many communication protocols in use, the integration of a spark tester into a centralized control system can pose difficulties. Clinton modules offer flexibility for integration with a computer or PLC.

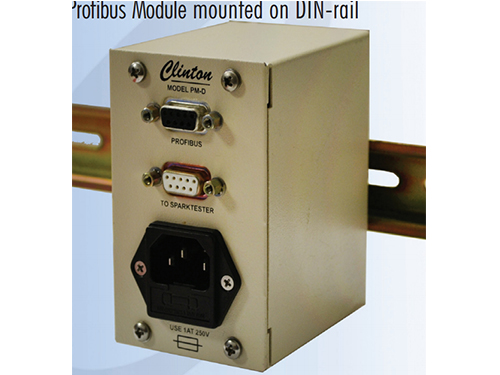

Clinton’s communications modules are inexpensive plug-in accessories that permit computers and PLCs to control and monitor the test voltage, fault count, and process control output of Clinton digital spark testers by analog signal, Ethernet, or Profibus. Each communication module can be connected to the spark tester’s standard RS-485 port or mounted remotely on DIN-rail.

Ethernet Module

The Ethernet module complies with standard Modbus/TCP protocol. The module may receive an IP address from a DHCP server or the Clinton spark tester during setup.

Profibus Module

Through the spark tester display or the serial port of a computer, an operator assigns the Clinton Profibus module a Profibus address, usually a number ranging from 0 to 128. The spark tester is now ready to communicate through standard Profibus protocol with virtually any Profibus master on the production line.

Analog Module

Clinton’s Analog module allows older production lines the ability to control and operate any digital Clinton spark tester through 0-10VDC analog signals.

AC Test Module with a Computer or PLC: