+Categories

|

SENSOPTIC supplies automatic measuring systems for continuous monitoring of surface defects and short diameter irregularities to improve product quality and reduce manufacturing costs of:

Monofilaments for industrial and medical applications

Bare and coated wires for the electronics industry

Optical fibers for telecommunications

Features

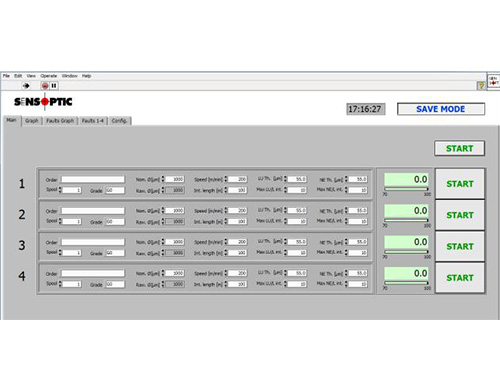

Can be fully integrated into any manufacturing process for continuous on-line quality control of multiple lines

Portable configurations for off-line sample inspection in production or laboratory environments

Runs on Windows based ordinary personal computers

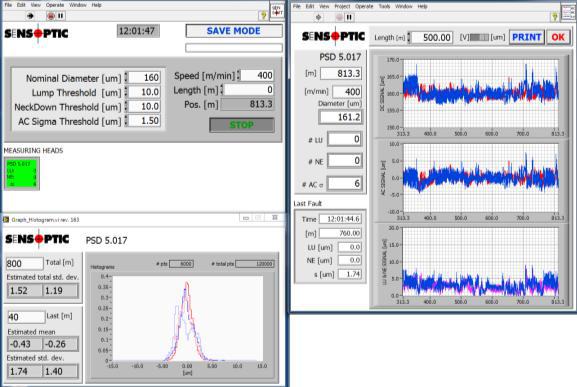

Multi-function, reliable and user-friendly SENSOFT

software

Up to 32 PROFILE SENSORS connected to one SENSYSTEM unit controlled by a single personal computer

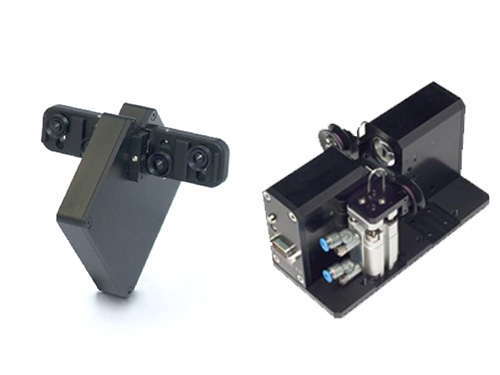

Configurations available for single-axis and dual-axis measurements, diameters from 0.01 mm to 4 mm and line speeds up to 2000 m/min

Features

Continuous monitoring of single or multiple lines with the same filament diameters and speeds

Real-time visualization of statistics and quality parameters

Intelligent detection of faults beyond specified threshold values

Automatic data recording and data saving for post-processing

Elaboration and printing of production quality reports