PDC-T Series

Inline Pinhole Detectors for Plastic Corrugated Tubing

Manufacturers of plastic corrugated tubing trying to located pinholes and flaws in their products find that in-line optical and laser systems are costly and complicated, and manual inspections after the fact are time-consuming, sometimes yielding high scrap levels. Clinton Instrument Company introduces the PDC-T In-Line Pinhole Detector, a low-cost, non-destructive system that instantly locates defects on the production line.

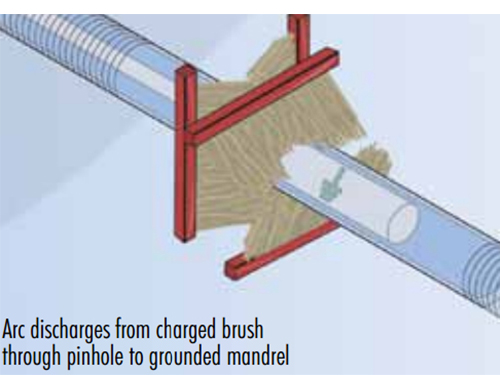

The system works by energizing the outer surface of a product with a high voltage bead chain or brush electrode, through which the product travels. The product rides over a grounded electrode, which can be an extension of the extrusion tooling or a metallic mandrel or carrier. If the product has a braided metallic reinforcement, this too can act as the grounded electrode.

Defect-free product will insulate these electrodes from each other. However, when a pinhole passes between the electrodes, a discharge through the hole will occur that is instantly detected and reported by the system.

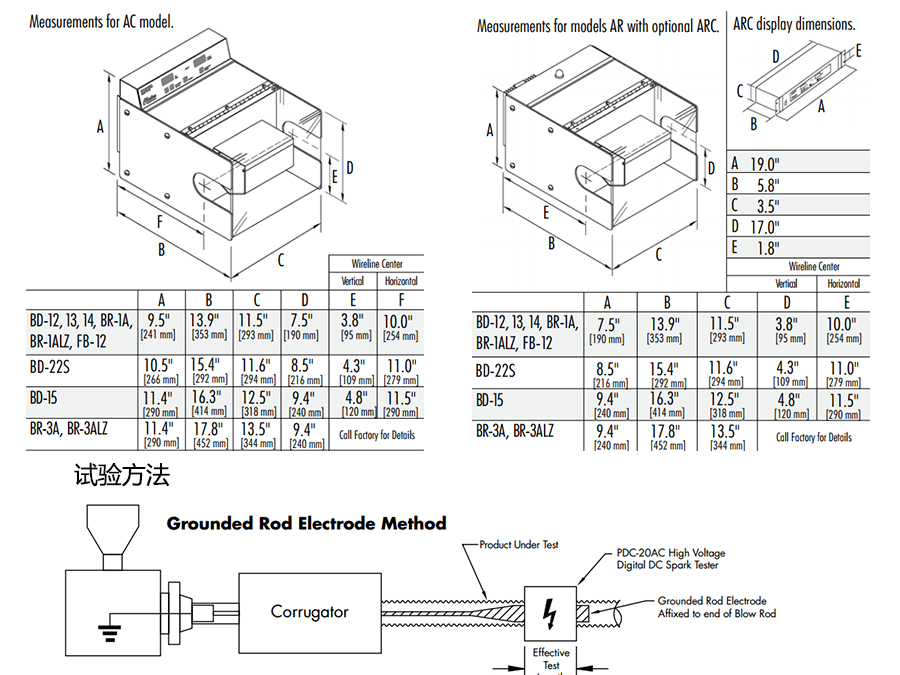

The system is available in three configurations:

An all-in-one unit

An electrode assembly located up to 200 feet away from a remote 19″ ARC control display

An electrode assembly that receives and responds to digital commands from a PLC or computer